Additional 6m x 3m Glaston Toughening Plant Installed.

Regency Glass have invested in an additional high specification toughening furnace. At 6m x 3m bed size, this will double our capacity to process toughened glass. Sitting alongside its ‘twin’ this new equipment will support current IGU and single toughened production.

A key reason for the upgrade, is to also meet demand for more toughened glass, as triple glazing volumes increase.

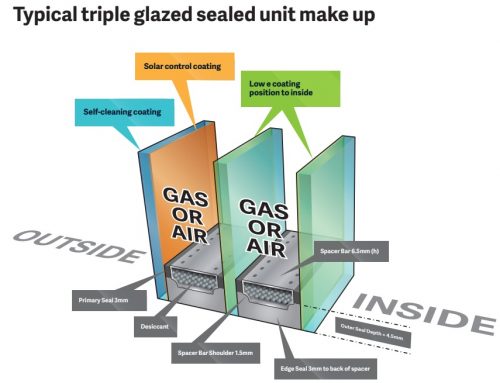

The middle pane of a high performance triple glazing unit (TGU) is recommended to be toughened to avoid cracks due to the increased and varying temperatures. The heat build up within a TGU, made up using 2 x high performance coatings, 2 x warm edge spacer and 2 x Argon gas filled cavities, may cause an annealed pane to become thermally unstable. This can potentially lead to breakage due to thermal heat stress. In our opinion, this risk and the cost of replacing these units, including the end users disruption, is not worth it when compared to the low cost of including a toughened middle pane.

The demand is expected to grow, initially in new build properties, with the run up to FSH standards in 2025, requiring whole window U-values to be 0.8W/m2.K.

Whilst there are other options such as Vacuum glazing or ‘heat mirror’ films, these two ‘new’ ideas are not cost effective for mainstream high volume IGU production.

Triple glazing is the answer for most market applications.