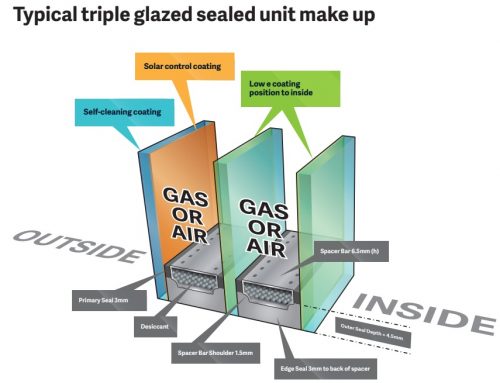

Argon & Krypton Gas filling and testing of sealed units

Inert gas filling of sealed units improves the thermal efficiency of glazing. Argon and Krypton are denser than air and therefore act a an additional thermal barrier to heat escape.

Argon is widely used due to cost and its good performance across a range of double and triple glazing cavities, improving U-values by up to 0.2W/m2.K.

Krypton is used in units with narrow cavities 8-12mm to help them achieve better U-values in specialist glazing.

Modern high volume sealed unit production requires Argon gas filling online, during the production process. The latest incarnation of on line gas filling is a tandem gas press, that enables two units to be Argon filled at the same time. Regency Glass have invested in two of these high speed production lines.

Once the units have been gas filled, it is important to seal them quickly to prevent gas loss. Here, Regency have invested in two Bystronic speedline sealing robots that immediately seal the unit, giving excellent gas volume rates of +90%.

We test daily using one of our two Sparklike non-invasive gas testers. These are set up for Argon and Krypton and are calibrated annually by the manufacturer in Finland under our EN1279 accreditation.

Gas tester in action.