Q.

Trade- When do I need to move to 6mm glass thickness rather than standard 4mm?

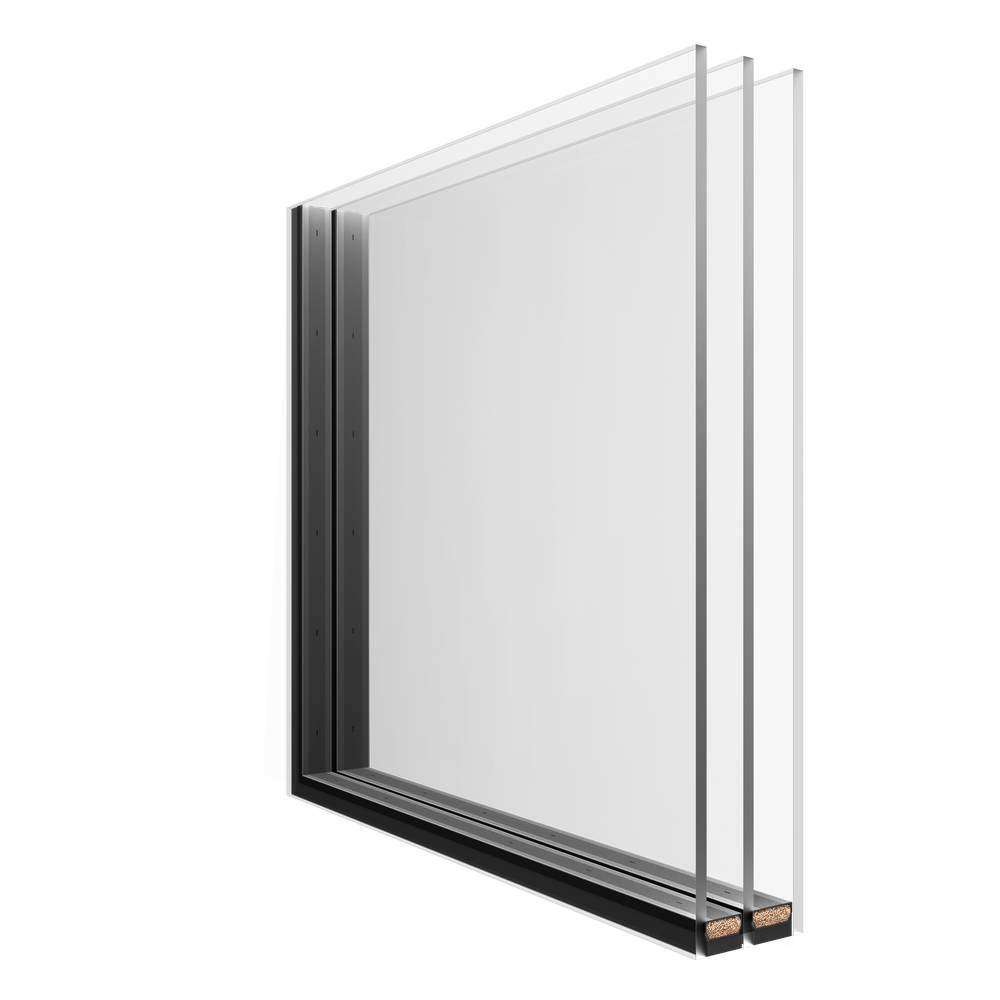

A.When it comes to glazing performance and structural integrity, glass thickness matters. While 4mm glass offers flexibility and is suitable for smaller applications, we strongly recommend using 6mm glass for larger or longer insulating glass units.This reduces the risk of excessive flexing, which can cause glass breakage or unit failure over time. For any glazing unit exceeding 1300mm in both width and height, or where one dimension exceeds 2400mm, 6mm glass should be the standard for optimal strength, stability, and long-term performance.

Q.

Homeowners- My new glazing appears to have condensation on the outside, why is this?

A.Condensation is the result of moisture forming on cold surfaces, often seen on the outer pane of high-performance insulating glass units. This happens because modern glazing is designed to significantly reduce heat loss from your home, keeping warmth inside and causing the external glass surface to remain colder.As a result, condensation may form on the outer side of the insulating glass. This is a normal effect of efficient glass systems and typically occurs only during specific weather conditions or certain times of the year and usually for short periods.

For more information, view the GGF Condensation Brochure download in the Quality section of our website: https://www.regencyglass.co.uk...

Q.

Glass Quality- On close inspection of my new windows and glazing, I can see marks in the glass. Is this normal?

A.The glass and glazing industry follows a recognised visual quality standard to assess the appearance of installed products. According to these guidelines, toughened glass, Low-E glass and laminated glass should be inspected from a minimum distance of 3 metres.When viewed on a dry day, in natural but indirect sunlight, no marks, blemishes, or imperfections should appear visibly intrusive through the glass. This standard ensures that all glazing meets high aesthetic and performance expectations for both residential and commercial applications.

For more information, view the GGF Quality of Vision download in the Quality section of our website: https://www.regencyglass.co.uk...

Q.

Trade & Homeowners- Can you make square cut outs in glass for cat flaps?

A.No. This is because the internal angle will ‘run’, so the glass continues to break across the straight line. We can do circles, and circular cat flaps are available.

Q.

Trade- What is the minimum cavity thickness for an IGU containing Georgian bars?

A.Our Georgian bars are designed at 8mm thickness, with anti-rattle centres that add a few extra millimetres for enhanced stability and noise reduction. Due to this, we recommend a minimum cavity size of 12mm when incorporating Georgian bar profiles into insulating glass units.This ensures optimal fit, durability, and performance in all glazing applications.

Q.

Trade & Homeowners- I need noise reducing glazing, what do you offer?

A.Regency Glass can manufacture glazing to meet any noise reduction target. Firstly, the decibel reduction sought needs to be determined, and we can build glazing to achieve this. Please note that in a 28mm space and still achieving performance, the choice is limited; necessary thermal performance and 40db rw reduction are about as good as they get. This is 6.8mm acoustic laminated/16mm Argon cavity / 6mm Low-E.

Q.

Homeowners- My glass appears to have unexplained marks that cannot always be seen but show more when the sun shines. What is this?

A.This could be due to several things, but the Low-E coating usually reflects the sunlight at different angles. The ‘marks’ seem to disappear when the sun isn’t shining. This is normal and varies across the day as the sun moves across the sky. They are reflections of light or processing marks that cannot be seen under normal viewing conditions.

Q.

Homeowners- I am thinking of having new windows and have heard many claims that triple glazing is much better than double glazing. What is best?

A.Triple glazing can be better, but it is essential that the right glazing make-up is specified. This needs to be a minimum of 4mm clear glass/8mm Argon/4mm low e glass/8mm Argon/4mm Low-E glass. At 28mm glass unit thickness – industry standard- this is possibly worse than double glazing and may not be worth the extra cost. Widening the units to a minimum of 36mm will be beneficial and offer up to 50% improvement over double or narrower triple glazing. Use our 'Glass for your home' tool on the homepage to help recommend the right glass!

Q.

Homeowners- The decorative lead designs on my glass have gone all discoloured and mottled. What has happened?

A.Natural lead is a soft metal, and when in the atmosphere, it will rust! This oxidation process can take a variable amount of time but will ultimately result in a dull grey patina that remains constant.

Q.

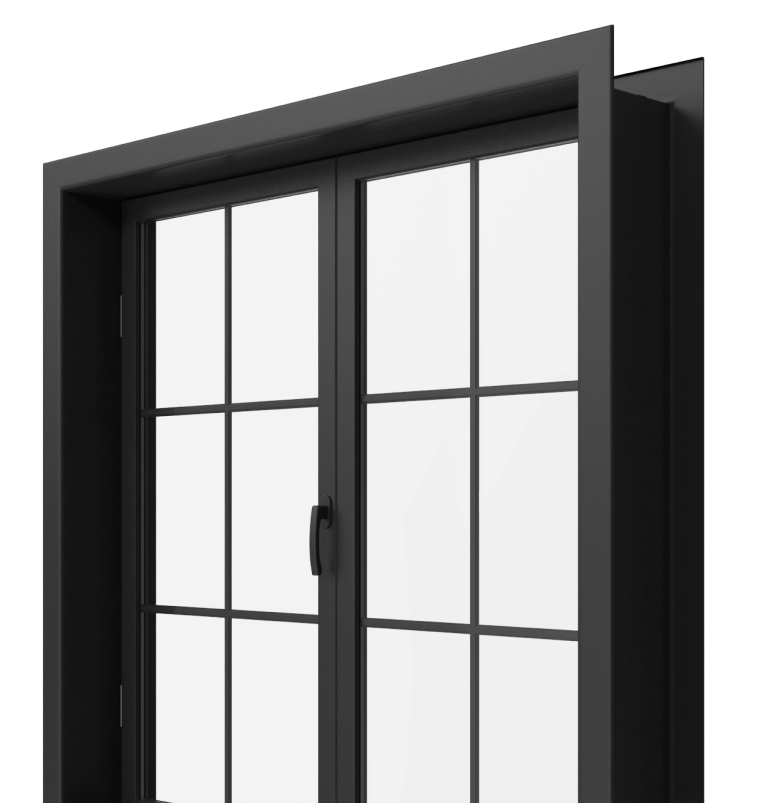

Safety Glass vs Security Glass- What is the difference between toughened and laminated glass?

A.Toughened glass, often referred to as safety glass, is designed to shatter into small, blunt fragments upon impact, minimising the risk of injury. While this makes it ideal for general glazing applications, it also creates a wide, unobstructed opening when broken, offering little resistance to break-ins—particularly in settings like patio doors.By contrast, laminated glass is classified as security glass due to its layered construction. When it breaks, it remains intact, holding together and reducing the risk of injury while maintaining a secure barrier. This high-resistance property makes laminated glass far more difficult and time consuming to penetrate, often deterring forced entry attempts.In fact, police forces across the UK consistently recommend laminated security glazing to enhance property protection and combat crime effectively.