Regency Glass Invests in HEGLA Machinery and Technology for Ultra-Thin TGUs

Regency Glass, a leading UK insulated glass unit manufacturer (IGUs), is proud to announce a multi-million-pound investment in cutting-edge machinery from long-term partner HEGLA. This machinery purchase will support the launch of Regency’s revolutionary new product: ultra-thin triple-glazed units featuring a 0.5mm glass centre pane—a product currently unavailable elsewhere in the UK.

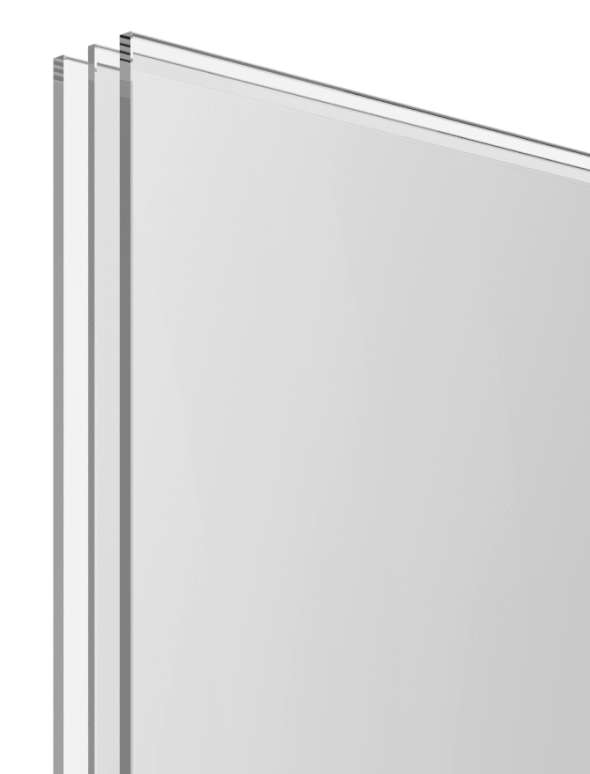

Significantly Reducing the Thickness and Weight of IGUs

Traditional triple-glazing has long been associated with added weight and bulk, making it challenging for certain window systems and architectural applications. Regency’s new ultra-thin triple-glazed units directly address these issues by significantly reducing the overall unit thickness and weight without compromising energy efficiency or performance. This innovative new product reinforces Regency’s reputation for high-quality and service.

Regency Glass has acquired a suite of advanced machinery from HEGLA to support this leap in UK glazing, including two thin glass cutting tables and multiple sort jets.

This cutting-edge equipment enables the precise handling and processing of ultra-thin glass, allowing Regency to scale production of its innovative triple glazing solution with exceptional speed, consistency, and quality. The fully automated, high-efficiency factory setup places Regency at the forefront of UK IGU manufacturing, setting a new benchmark for innovation and operational excellence.

“Triple-glazing has always offered higher performance benefits, but weight and thickness have limited its wider use,” said Bradley Beazant, Chief Development Officer at Regency Glass. “This new product is a genuine breakthrough. By collaborating with Corning Incorporated and using their 0.5mm glass as a centre pane, which withstands thermal stress, we’ve developed a solution that delivers the energy performance of triple glazing with a weight comparable to a double-glazed unit. With HEGLA’s machinery and support, we’re setting a new standard for what’s possible in the UK glazing market with a partner we can trust to deliver.”

The collaboration between HEGLA and Regency Glass is based on a long-standing relationship and a push for innovation and technical excellence.

High Automation for Highly Efficient IGUs

“The level of automation in this project, achieved using our Sortjet advanced glass handling solution, will make this the most technologically advanced IG factory in the UK. Hegla have always been the de facto standard for glass cutting in the UK, but we have yet to have the opportunity to showcase any of the proven automation machinery we have been producing for over 30 years worldwide. Our partnership with Regency Glass is now approaching 10 years. As a company, they have always sought out the most up-to-date solutions, allowing them to continually push the boundaries of manufacturing excellence. This new project showcases the next stage in advanced IGU production and opens up new markets with highly efficient, thermally insulating windows – for renovations, new buildings, and situations where existing frames are to be preserved. I am looking forward to our continuing collaboration with Regency Glass through this project," said Greg Smith, UK Managing Director at HEGLA Machinery.

For further information on our new product, which will be launching soon, please contact:

Steve Massey, Chief Sales Officer at Regency Glass.

E: stevemassey@regencyglass.co.uk

T: 01942 262 162